SPICAP Inspection Codes – Features & Benefits

When you purchase the SPICAP – Codes, you receive a spreadsheet/list that you can use for the following:

- Distribute to inspectors, engineers, consultants an others to clarify a standard inspection code set to be used on pipe inspections.

- Provide to your pipe inspection software administrator or vendor to add these codes and standardize your inspection software. The majority of software vendors will add SPICAP to your software at no cost with an active support agreement or maintenance.

- Use in your inspection software to easily filter and query and determine pipes that need repairs and/or maintenance.

- Give to contractors performing pipe inspections for your agency, standardizing incoming work product so that your software vendor can then import incoming work into your software of choice and contract work can easily become part of your projects for planning.

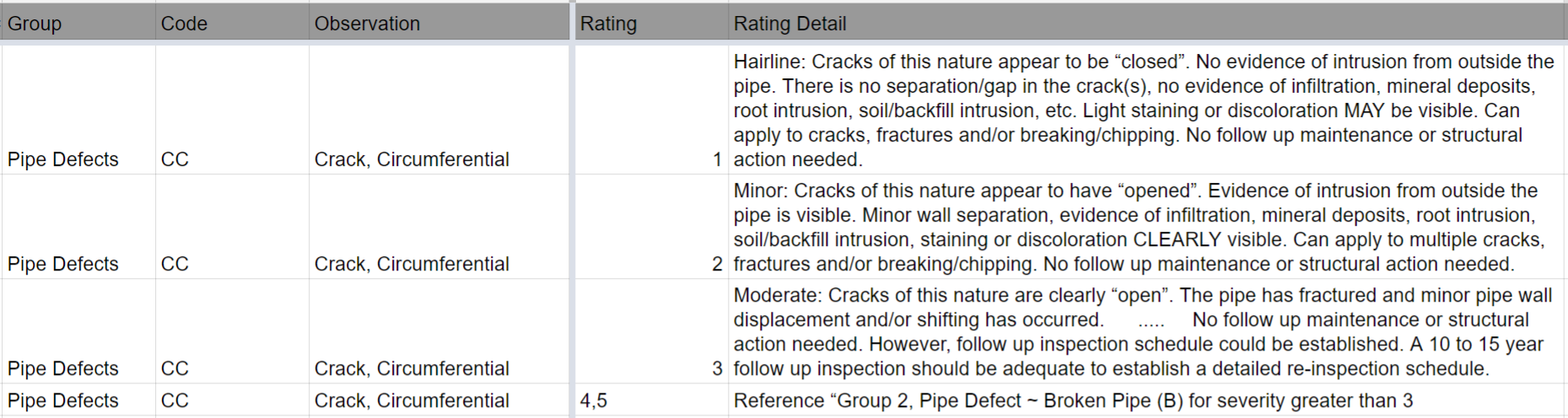

SPICAP Codes Detail

The SPICAP “Inspection Codes” includes a list of recommended observation codes and related detail to use for performing condition assessment on inspections. SPICAP uses the following 7 primary categories to organize the inspection codes. This includes:

- Common Text/Others: Describes common events not accounted for in other groups.

- Pipe Defects: Describes structural and infiltration events.

- Operations & Maintenance Issues: Describes maintenance related events.

- Service Tap Connections: Describes house connections.

- Service Laterals: Describes defective house connections.

- Grade Alignment: Describes changes in pipe direction or alignment.

- Lidar/Laser/Sonar (specific to MSI): Describes Laser and/or Sonar related events.

For each category, there are multiple observations available. For each observation available, the spreadsheet contains the following:

- observation code acronym

- brief observation description that is used for coding inspections

- observation severity ranking

- observation description in detail

- parameters required for observation including details such as clock position, multiple clock positions, percentage, value such as size, comment, continuous start/end for linear defects

Here is a sample of detail on a specific observation showing the obs code acronym, the brief description used by the operator, the severity ranking, and the detailed description available in spreadsheet.